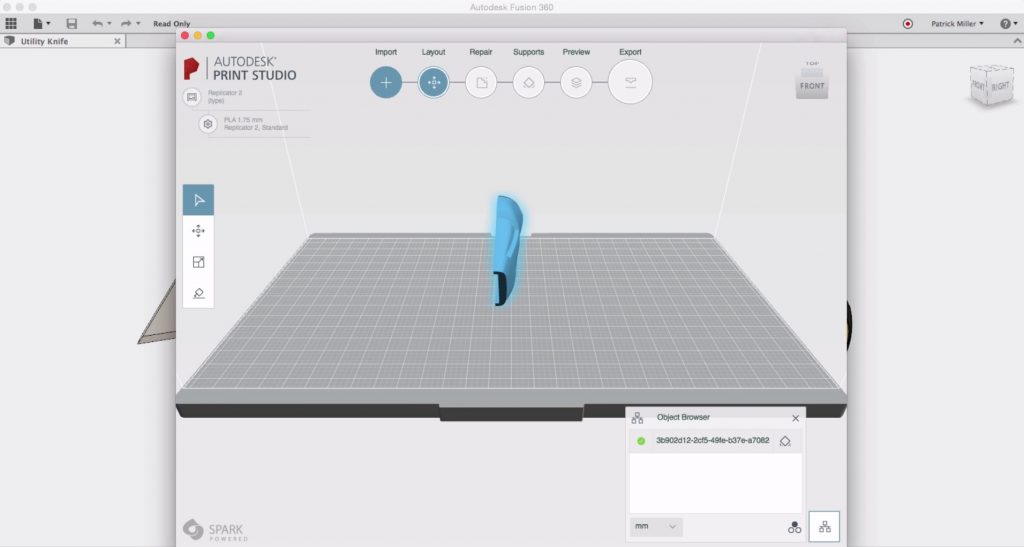

Post processing is effectively a translation of the program from the computer’s language to the printer’s. The final step before starting your 3D print is to post process. The simulation will show green lines, representing the actual path the nozzle is going to follow, as well as showing the results of the previous layers, as seen in the image below.

Fusion 360 3d printing how to#

This is helpful when breaking down your prints, as it allows you to look at complex aspects, such as bridges and/or overhangs, and may allow a better perspective of how to alter layer height to provide a better outcome. Users can view individual layers, or simulate the entire print. This will also allow you to see how the supports will look like. Once you have generated the toolpath, you can simulate it, to see how your printer is going to behave.

Fusion 360 3d printing code#

This will compute the path of the nozzle, forming the basis of the code your printer will use. Once you selected these settings, you can generate the toolpath. For example, you can set a higher layer height, quicker print setting for faster prototyping, and potentially a lower layer height and slower print setting for final products. By doing this, you can create pre-sets, so that you don’t have to change this each time. Once you have edited them, you can save your settings. From commonly adjusted settings, such as layer height and infill density, to more advanced settings, such as print temperatures and speeds, the whole process can be controlled in as much detail as you desire. The Settings dialogue will control the 3D print itself. Criteria can be ranked in order of importance to give the algorithm more information regarding the desired print orientation. This will analyze the model to derive optimized orientations, allowing support structures to be minimized, for example. Brought in from Netfabb, this feature was originally designed to help reduce problems inherent to printing metal parts, but can apply to plastics as well. Alternatively, the Automatic Orientation may be beneficial. There is also a Minimize Build Height function to limit the total Z height of the part, helping to reduce errors associated with tall prints.

Fusion 360 3d printing manual#

You may want to use the more manual Move and Place Part on Platform commands to orient the layer grain along the model. You can do this in several ways, depending on the desired outcome. Once you’ve created your setup, you now must orient the part. This is how it knows what it’s going to print!įusion FFF (Fused Filament Fabrication) printing: Orienting your part Don’t forget to select the part you want to print as the Model within the setup. Within your setup, you can specify the machine that you want to print on, along with the print settings and other features (we will cover those later on). For those of you who have experience in manufacturing within Autodesk Fusion 360, this will be a very familiar experience. Now that you are in the Additive environment, you are ready to start setting up the 3D print. Then select the Additive Manufacturing tab at the top of the window. To begin 3D printing in Autodesk Fusion 360, switch to the Manufacture workspace. The first step, when it comes to setting up your print, is to define your setup.

The part is the fixture used to secure an additively manufactured part during the post machining process.

To help outline this workflow, we will focus on a part designed as part of a project involving NOV (National Oilwell Varco), Renishaw, and Autodesk. At a high level, the basic steps include setup, generation, and simulation. The recommended workflow for Fusion Fused Filament Fabrication is very similar to that of our other manufacturing environments. This article will run you through a brief introduction to Fusion FFF printing, to help you set up your own prints. It also allows for integration with multiple brands of machines directly from the software, by changing the machine file and post-processor. Simply regenerate the toolpath with the updated model and you’re good to go. End-to-end integration allows to quickly translate any design changes into changes in the print files. Simply switch workspaces, follow a few quick steps and you’re ready to go! You are probably wondering “why is this so useful?”. Gone are the days of exports and imports. FFF ( fused filament fabrication) printing allows users to print straight from their 3D design software. In the latest Fusion 360 update, we unveiled the brand-new Fusion FFF printing.

0 kommentar(er)

0 kommentar(er)